Other sludge thickening processes

Membrane thickening processes

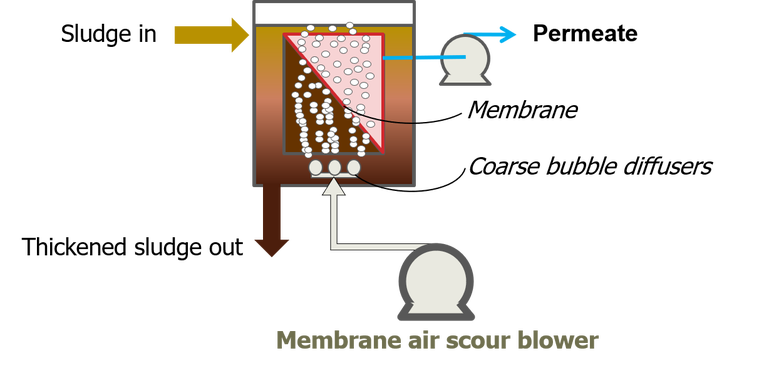

Membrane technology provides separation of suspended solids from liquid though a highly-selective permeable polymeric or ceramic material. In principle, membranes can be used to thicken sludge so that water is extracted through the membrane, allowing the sludge solids concentration to increase accordingly.

Membranes provide 100% suspended solids capture since the solids are completely rejected by the sub-micron pores of the membrane. The quality of the filtrate, i.e. the extracted water, produced is therefore extremely high.

However, the cost of the membranes themselves, the relatively high energy consumption associated with the membrane air scour required to keep the membranes clean, and the limited degree of sludge concentration attainable using membranes means that its practical applications are limited. Membrane thickeners normally achieve no more than a 4% DS (dry solids) thickened product for a waste activated sludge (WAS) feed.

Membrane thickeners are sometimes installed on the sites of membrane bioreactors (MBRs) where the same flat sheet membrane technology used for the MBR is also employed for thickening. In such cases the flux through the design flux for the membrane thickener is 50-60% of the value for the MBR, and the air scour rate higher. This mitigates against clogging of the membrane channels by the thickened sludge.