Sludge treatment − gravity thickening

How gravity thickening works

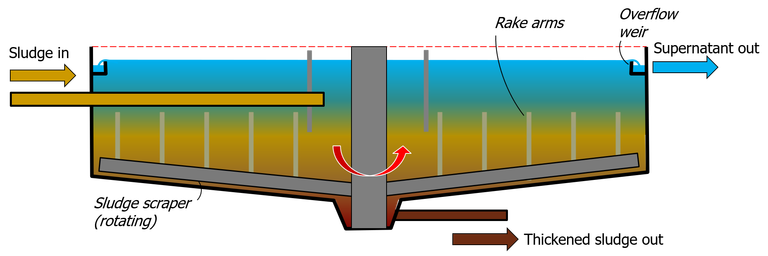

Gravity thickening increases the solids concentration by allowing the particles to settle to the base of a vessel, producing a concentrated (thickened) solids stream at the vessel base and a supernatant (diluted) stream at the surface.

Sedimentation, or settling, is the simplest of the thickening processes. A gravity sludge thickener has the same design features as a primary sedimentation tank used for wastewater treatment, and most often has cylindrical geometry.

A common variant on the gravity thickener design is the picket fence thickener. This technology is fitted with a stirrer comprising a series of relatively closely-spaced vertical arms, and is therefore similar in appearance to a picket fence.

For both designs, the sludge enters the centre of a cylindrical tank and flows out to the periphery. As water flows outwards from the centre, the suspended solids sink to the base of a cylindrical vessel, where they are scraped into the cone-shaped outlet (underflow) by a rotating scraper and removed as the thickened sludge product stream. The diluted supernatant stream reaching the tank wall then flows over a weir at the surface (overflow) and is usually directed back to the inlet of the wastewater treatment works.

Gravity thickener principles (Indian School of Mines)

Gravity thickeners generally retain 80−90% of the solids in the thickened product stream, depending on the sludge characteristics and the efficiency of the preceding conditioning stage. The sludge characteristics also govern the solids loading rate (SLR), which is the rate in kg/d at which the sludge dry solids enter the process per unit process cross-sectional area.

Gravity thickeners are widely used for primary and mixed sludges, but are less effective for waste activated sludge (WAS).

| Sludge source | Solids concentration, % Feed | Solids concentration, % Thickened | SLR1 kgDS/(m2d) |

|---|---|---|---|

1SLR Solids loading rate | |||

| Primary | 2−7 | 5−10 | 100−150 |

| Waste activated sludge (WAS) | 1−3.5 | 2−5 | 20−30 |

| Extended aeration activated sludge | 0.2−1 | 2−3 | 25−40 |

| Trickling filter (TF) | 1−4 | 3−6 | 40−50 |

| Rotating biological contactor (RBC) | 1−3.5 | 2−5 | 35−50 |

| Anaerobically-digested (AD) primary | 8 | 12 | 120 |

| Mixed, primary + mixed liquor | 0.5−1.5 | 4−6 | 25−70 |

| Mixed, primary + WAS | 2.5−4 | 4−7 | 40−80 |

| Mixed, primary + TF | 2−6 | 5−9 | 60−100 |

| Mixed, primary + RBC | 1−6 | 3−8 | 50−90 |

| Mixed, AD primary + WAS | 4 | 8 | 70 |

The hydraulic load associated with the water in the sludge is routinely lower than the hydraulic loading rate (HLR) − the required rate at which water enters the process per unit cross-sectional area − which is usually 20−30 m3/(m2d). This flow cannot be achieved for most sludges at the maximum achievable SLR values unless they are extremely dilute. To maintain this HLR range, which is needed to suppress septicity within the sedimentation tank, recycling of part of the clarified product stream is required. This recycled flow often makes up more than 80% of the feed stream to the gravity thickener.