Sludge treatment − dissolved air flotation thickening

How DAF works

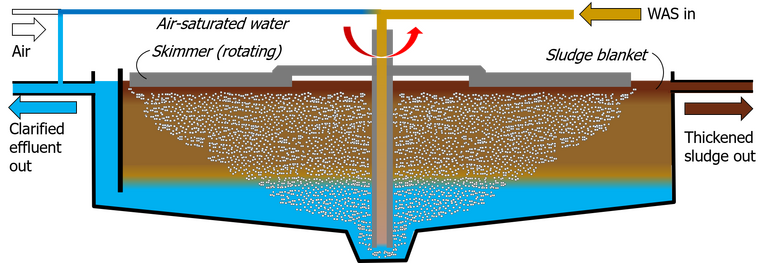

Dissolved air flotation (DAF) provides thickening of sludges (i.e. thickens the sludge) by encouraging the solids to float to the surface, rather than allowing them to sink as in gravity thickening.

DAF is applied to increase the sludge solids concentration when these solids are neutrally buoyant (i.e. neither sink nor float) and so cannot be readily removed by settling. This is usually the case for waste activated sludge (WAS) which demands a relatively low solids loading rate (SLR) of 20−30 kg dry solids per m2 tank area per day (kgDS/(m2d)) if treated by gravity thickening, compared to almost five times this rate for DAF. Polymer dosing at 2−5 g polymer per kg DS (g/kgDS) increases the SLR value further through generating larger flocs of greater buoyancy.

| Sludge source | Solids loading rate (SLR), kgDS/(m2d) without chemical conditioning | Solids loading rate (SLR), kgDS/(m2d) with chemical conditioning |

|---|---|---|

| Activated sludge mixed liquor | 30−70 | ≤240 |

| Waste activated sludge (WAS) | 50−120 | ≤240 |

| Trickling filter (TF) | 70−100 | ≤270 |

| Primary | 100−150 | ≤300 |

| Mixed, primary + WAS | 70−150 | ≤270 |

| Mixed, primary + TF | 100−150 | ≤300 |

Huber DAF process (HDF)

The DAF process works by dissolving air under pressure in water to achieve saturation concentrations. When the pressure is released, air is precipitated as small bubbles which rise through the vessel. The bubbles come into contact with the sludge particles, sweeping them up to the surface where they form a scum. The scum is then removed by a scraper. Part of the clarified effluent is used to form the air-saturated water (recycle) stream.

The effectiveness of the process is determined by:

- the sludge origin

- the air to solids ratio

- the recycle ratio, and

- the sludge blanket thickness.

Primary sludges are less effectively treated by flotation than secondary sludges because the particle density is higher. They also have an appreciable grit content which settles on the bottom of the DAF unit. DAF thickeners are fitted with scrapers – as with gravity thickeners – to collect the sediment.

The air to solids ratio is the mass of air employed per unit mass of sludge solids. For sludge thickening applications, this ratio is normally in the range 0.02−0.06 kg air/kg DS.

The concentration of air in the recycle stream is determined primarily by the pressure, since gas concentration increases with pressure. The amount of air available for flotation is determined by the recycle ratio, which is the ratio of the recycle flow rate to that of the influent sludge.

The thickness of the floating sludge blanket can be controlled by the speed of the surface sludge scrapers, the blanket thickness decreasing with increasing scraper speed. The sludge blanket must be thin enough to limit the risk of solids carrying over into the clarified effluent. A thickness of 150−200 mm is normally sufficient to limit carry-over to a maximum clarified effluent solids concentration of no more than 100 mg/L.