Sludge treatment − sludge dryer configurations

Sludge dryer configurations

Sludge drying processes generally take three forms:

- convective (or direct)

- conductive (or indirect), and

- solar.

Convective (or direct) dryers are the most commonly used type of dryer for sewage sludge. The sludge particles are in direct contact with hot gas – air or steam – which provides the heat required to evaporate the water. Since the process demands a significant volume of air, the air is often recirculated prior to venting, to conserve energy.

Convective dryers can be configured as:

- conveyer belts

- fluidised beds

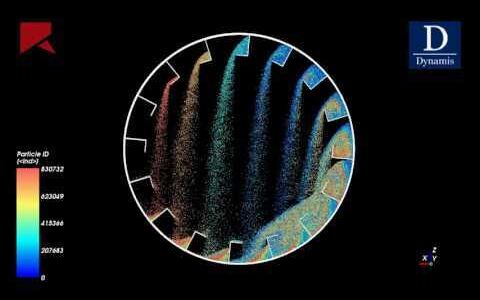

- rotating drums, or

- flash (or pneumatic) dryers.

Most convective dryer configurations require operation with backmixing of part of the dried sludge product stream with the feed to prevent the sludge going through the sticky phase.

For conduction drying, the sludge is heated indirectly by bringing it into contact with a surface which is heated either by steam or a hot oil system. Examples of conductive processes include:

- paddle dryers

- disc dryers, and

- thin film dryers.

Solar dryers take the form of large greenhouses into which the sludge is fed either continuously or in batches.