Sludge treatment − properties of drying sludge

Overview of sludge drying properties

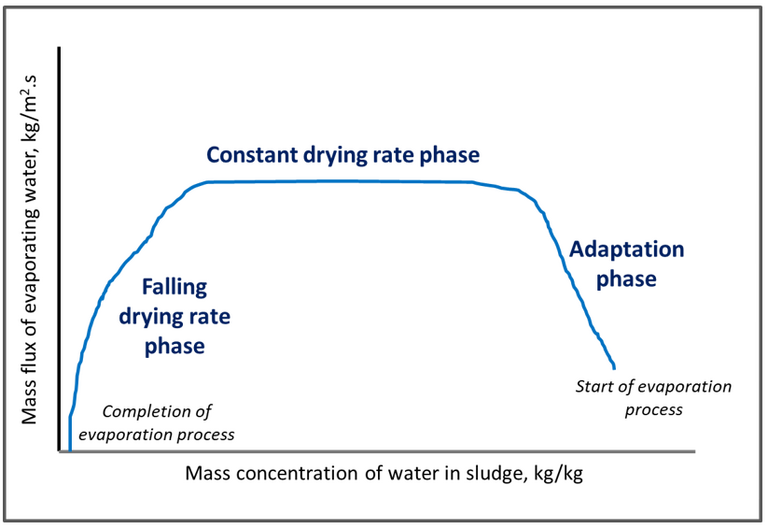

When sludge dries, it goes through three different phases as the water evaporates:

- the adaptation/preliminary phase

- the constant drying rate phase, and

- the falling drying rate phase.

During the adaptation/preliminary phase, the rate of water evaporation rapidly increases to a near-constant value. The process then continues at a near-constant drying rate until the most accessible free water has been removed.

Sludges of different origins and characteristics exhibit different behaviours when drying. These are most readily observed by correlating the mass water flux – the mass of water evaporated per unit surface area of solids per unit time (kg m-2 s-1) – against the moisture content of the sludge. This correlation normally reveals the three different drying phases.

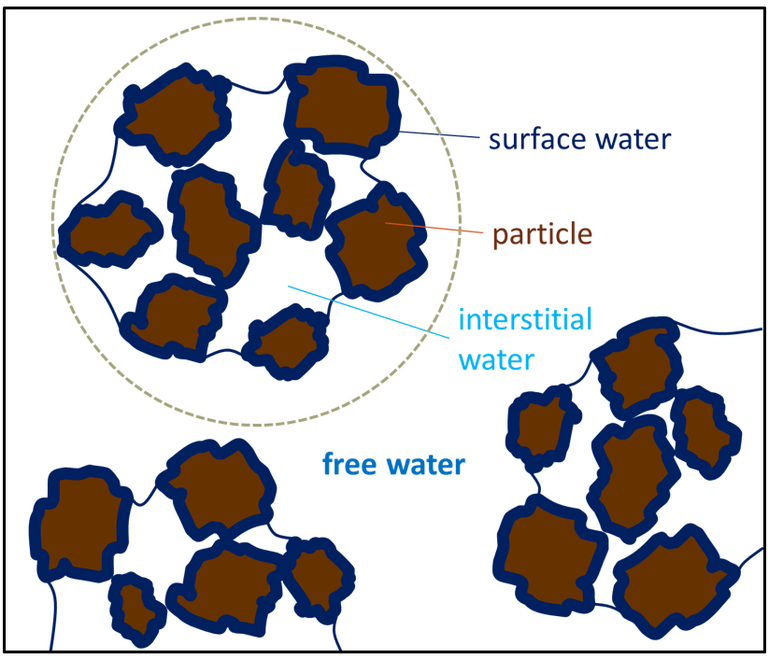

Following the removal of most of the free water – the water unassociated with the flocs – the drying rate reduces, corresponding to the falling drying rate phase. This phase may itself have two recognisable zones, respectively corresponding to the removal of:

- a) the interstitial water – the water held within the flocs but not associated with the solids, and

- b) the surface water – the water associated directly with the solid particles and bound to their surfaces by hydrogen bonding.

Evaporation of more than ~95% of the total water is not normally viable or necessary. The last 5% of the moisture relates to the surface water, which is much less easily removed. Thermal drying therefore generally aims to remove most of the interstitial water alongside the free to produce a product of~90% DS or more.

Sludge of ~10% moisture content or less is stabilised, easily conveyed (since it is in granular or powdered form) and generally suitable for either:

- end use, for example, as a soil conditioner, or

- processing by ’dry‘ thermochemical methods such as incineration, pyrolysis or gasification.

The sludge drying curve can be used to determine key dryer design parameters such as temperature and residence time. The rate and extent of drying impacts of the mechanical properties of the sludge, which change significantly in the course of the drying process as the water content decreases:

| Solids mass concentration (% DS, dry solids) | Sludge mechanical properties |

|---|---|

| < 40% | At the start of the process – when the moisture content is at its highest and the evaporation rate is increasing – the sludge resembles a paste, and is said to be ‘pasty’. |

| ~40 – ~50% | The sludge starts to form lumps and becomes ‘sticky’ and difficult to manipulate. |

| >70% | At the point at which there is insufficient moisture to sustain these lumps, they collapse to form granules or a powder. |

Sludge drying demands careful control. Dryers are normally designed to avoid the ‘sticky’ phase to prevent handling problems and form a free-flowing granular or powdered product. This is achieved either through backmixing or agitation.

For backmixing, the influent dewatered sludge is blended with some of the pre-dried granular material from the dryer to provide a sludge product where the average water content is below that associated with the sticky phase. This mixed product is then fed into the dryer to reduce the water content further.

Agitation avoids the formation of sticky sludge by efficiently mixing the sludge during the problematic sticky phase in order to maintain its movement throughout. This ensures that the lumps quickly disintegrate before they can become sticky.

Control of the sludge properties during drying is critical. Under certain conditions, and for certain sludge characteristics, the sludge dust particles can explode or the solids self-combust. These risks can be reduced by blanketing with an inert gas.