Introduction to sludge drying

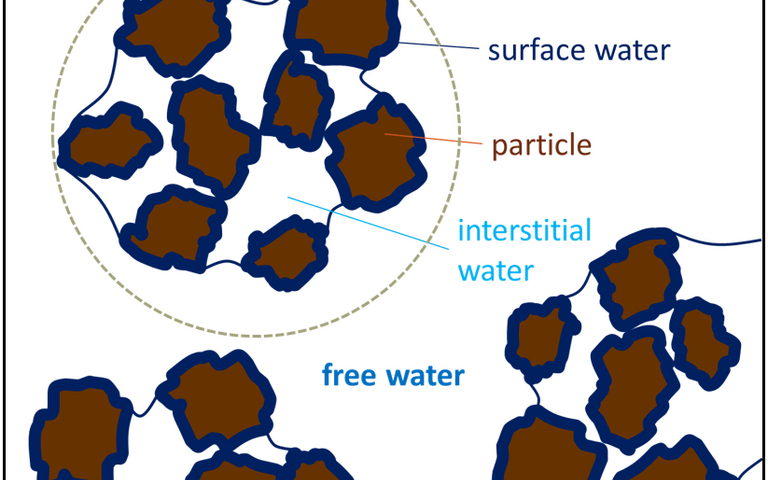

Sludge drying refers to processes where moisture is removed from sludge as water vapour. This is to be distinguished from processes where sludge is dried by purely mechanical means, such as thickening or dewatering where moisture is removed as a liquid.

Why dry sewage sludge?

There are three primary reasons why drying sewage sludge may be advantageous:

- to reduce the sludge water (or moisture) content and, therefore, the volume further than is possible by mechanical means

- to render the sludge suitable for treatment by certain thermochemical methods, principally incineration and pyrolysis, and

- to produce a stabilised product, i.e. one which is substantially free of pathogenic organisms and odour, and is not putrescent (i.e. susceptible to decay).

Reducing the moisture content increases the organic carbon concentration and so the calorific content of the sludge, normally expressed in units of mega-Joules per kg sludge dry solids (MJ/kgDS).

Other sludge stabilisation unit operations include anaerobic digestion (AD) and thermochemical methods. Thermochemical methods adopt more aggressive heating conditions than those employed for sludge drying, converting the solids to a stable char solid product alongside gaseous products which may or may not have a calorific value depending on the thermochemical method used.

Drying the sludge also substantially changes its nature and consistency. Sludge dried to >65% dry solids (DS) can exist either as pellets or, at the highest solids concentrations of 90% or more, as a powder. Both these forms are more readily conveyed than the dewatered sludge of higher water content, which exists as large lumps which can only be transported by conveyor belt.