Screw presses for sludge dewatering

How screw presses work

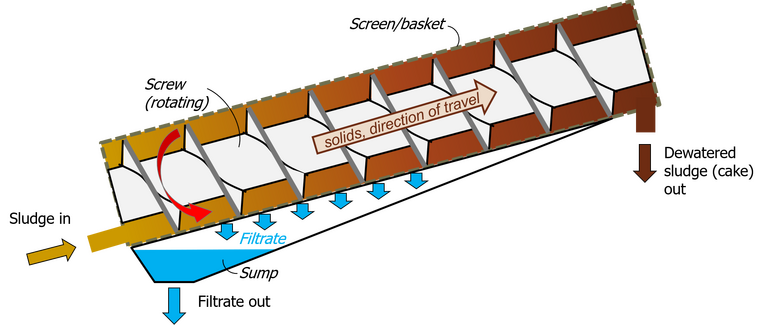

A screw press (SP) provides sludge dewatering by conveying the sludge along the inside of a permeable cylinder. It is based on a slowly-rotating (~5 RPM) Archimedean screw within a cylindrical screen (otherwise termed drum filter/screen or basket). It is normally inclined by ~20° to the horizontal to assist with the draining of water into the sump. The screen generally has an aperture rating below 0.5 mm and is based on wedge-wire or occasionally perforated metal.

The screens are less susceptible to clogging than the filter media used for other thickening and dewatering processes. Consequently, spray-cleaning is applied only intermittently for around 2−4% of the operating time.

As with all thickening and dewatering processes, the product solids (or cake) content is dependent on the feedwater sludge quality. The cake solids content has been shown to be inversely proportional to the volatile solids (VS) of the feed sludge.

Huber Q-PRESS® screw press

newsletterSignup is not templated

| Sludge origin | % cake solids | % solids capture | Polymer dose − g/kg DS |

|---|---|---|---|

| Primary | 30−40 | ≤90 | 4−10 |

| Waste activated sludge (WAS) | 15−22 | 88−95 | 8.5−11 |

| Anaerobically-digested (AD) primary | 22−28 | ≤90 | 10−17.5 |

| Anaerobically-digested WAS | 15−25 | 88−95 | 8.5−17.5 |

| Aerobically-digested, WAS | 15−20 | 88−95 | 8.5−17.5 |

| Mixed, primary + WAS | 25−35 | ≤90 | 5−10 |

| Mixed, AD primary + WAS | 17−25 | ≤90 | 10−17.5 |