Rotary presses for sludge dewatering

How rotary presses work

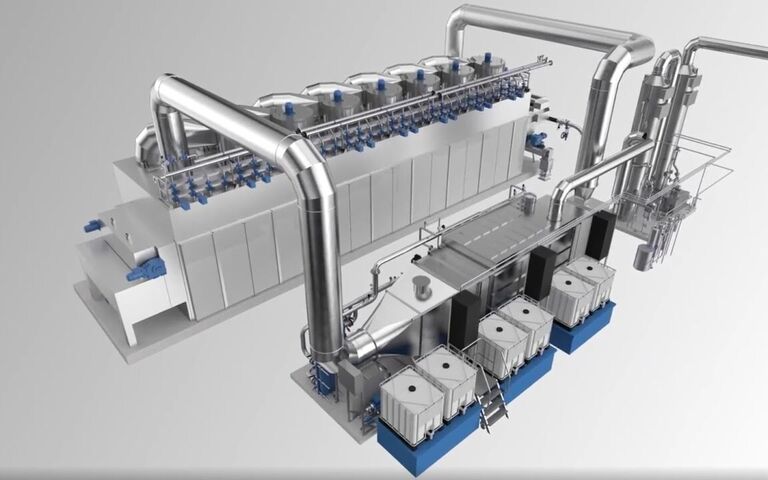

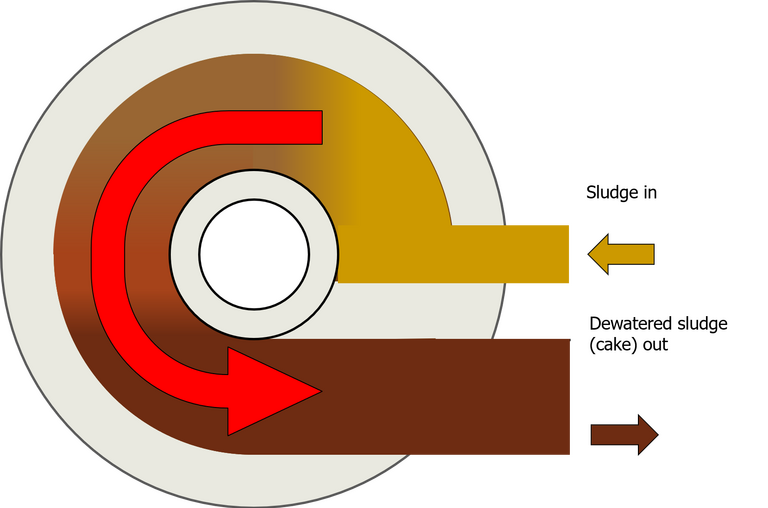

A rotary press is a dewatering technology which removes water by passing the sludge through a relatively narrow, rotating parallel-flow channel with porous walls.

The rotary press provides dewatering using a cylindrical vessel housing two slowly-rotating (at < 2 RPM) circular screens which are sandwiched together. The sludge enters the channel formed between the two screens and follows a circular path around the channel at a small applied pressure (0.1−0.5 bar). The combination of the applied pressure, generated through creating a restriction at the outlet, and the shear forces generated by the rotating action and the moving solids encourage the passage of filtrate through the two screens as the sludge travels around the channel.

The action and performance of the RP is similar to the screw press, which also operates at low speed and uses a fine screen to retain the sludge solids in the unit. Unlike the screw press and many other dewatering technologies, the RP screens cannot be operated with simultaneous filtration and spray-cleaning. Also, the filter area of a single RP is limited practically by the diameter of the unit (up to ~1.2 m). RP installations therefore normally comprise a number of parallel units: the technology is modular in nature.

However, the RP is relatively low in energy demand and is a completely enclosed system, providing very good odour control, and has low noise levels. The technology is well established, having first been implemented for sewage sludge dewatering in the mid-1990s.

| Sludge origin | Cake % DS | % solids capture | Polymer dose, g/kgDS |

|---|---|---|---|

| Primary | 28−45 | >95 | 2−6 |

| Waste activated sludge (WAS) | 13−18 | 90−95 | 12.5−17.5 |

| Anaerobically-digested (AD) primary | 22−32 | 90−95 | 7.5−10 |

| Anaerobically-digested (AD) WAS | 12−17 | 85−95 | 10−17.5 |

| Mixed, primary + WAS | 20−32 | 92−98 | 7.5−10 |

| Mixed, AD primary + WAS | 18−25 | 90−95 | 10−15 |

| Aerobically-digested WAS | 28−45 | 90−95 | 8.5−17.5 |