Introduction to sludge dewatering

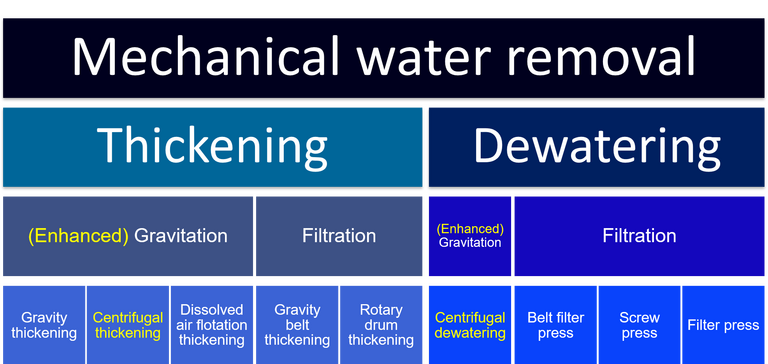

Overview of sludge thickening and dewatering

Thickening and dewatering processes both provide a concentrated, consolidated product − retaining most of the solids from the original sludge – along with a diluted stream which is predominantly water. For both process types the dilute stream is usually directed back to the inlet of the wastewater treatment works.

Thickening processes are those which concentrate the sludge by removing part of the free water. In doing so, the finished product retains the liquid, free-flowing characteristics of the feed sludge, so that it can still be conveyed by pumping. Thickening normally increases the dry solids (DS) content to 4−6%.

Unthickened sludge, ~2% DS

Unthickened sludge, ~2% DS Source: Paul Nelsen / YouTube Thickened sludge, ~6% DS, pumped into a bucket

Thickened sludge, ~6% DS, pumped into a bucket Source: Paul Nelsen / YouTube Thickened sludge, ~6% DS

Thickened sludge, ~6% DS Source: Paul Nelsen / YouTube Sludge going through a belt thickener

Sludge going through a belt thickener Source: Sidney Seckler Ferreira Filho / YouTube

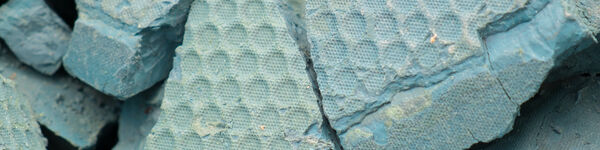

Dewatering processes remove significantly more of the sludge water content to produce a concentrated sludge product with a DS concentration generally between 15 and 45%. At this concentration the product, referred to as a cake, is not free-flowing and instead forms lumps which can only be transported by a conveyor belt, mechanical earth-moving equipment, or spade.

Dewatering processes apply a significant mechanical force to achieve increased water removal over that possible from thickening. These processes operate by:

- pressing the sludge to force the water (or filtrate) through a permeable medium (belt filter press, screw press, or filter press)

- rapidly rotating the sludge in a cylindrical vessel to force the denser solids to the internal walls of the vessel and the water to its centre, the water forming the diluted centrate stream (centrifugation)

- passing the sludge through a narrow, parallel flow channel with porous walls through which the filtrate passes (rotary press),

- allowing the liquid to evaporate under ambient conditions (sludge drying lagoons) or both evaporate and drain under gravity through a permeable medium on which the sludge sits, (sludge drying bed).

Characteristics of dewatered sludge

Dewatering processes can potentially remove both the free water and a proportion of the interstitial (or floc) water. The dewatered sludge, or cake, %DS content can range from 13−46% depending on the feed sludge characteristics and the dewatering technology employed (Table 1). At such high DS concentrations, the material is no longer free-flowing and can only be transferred by spade or conveyor belt.

| Sludge source | Filter press | Centrifuge | Belt press |

|---|---|---|---|

| Primary, raw sludge | 40−46 | 25−32 | 31−37 |

| Activated sludge or trickling filter | 27−33 | 14−20 | 13−20 |

| Digested mixed sludge | 29−35 | 20−25 | 20−25 |