Belt filter presses for sludge dewatering

These presses dewater sludges to produce a cake with a dry solids content of 30% or more in the case of primary sludge

Your web browser is out of date.

Update your browser for better security, speed and to get the best experience on this website.

Dewatering processes provide a concentrated, consolidated product − retaining most of the solids from the original sludge – along with a diluted stream which is predominantly water.

Dewatering processes apply a significant mechanical force to achieve increased water removal over that possible from thickening.

Learn more

These presses dewater sludges to produce a cake with a dry solids content of 30% or more in the case of primary sludge

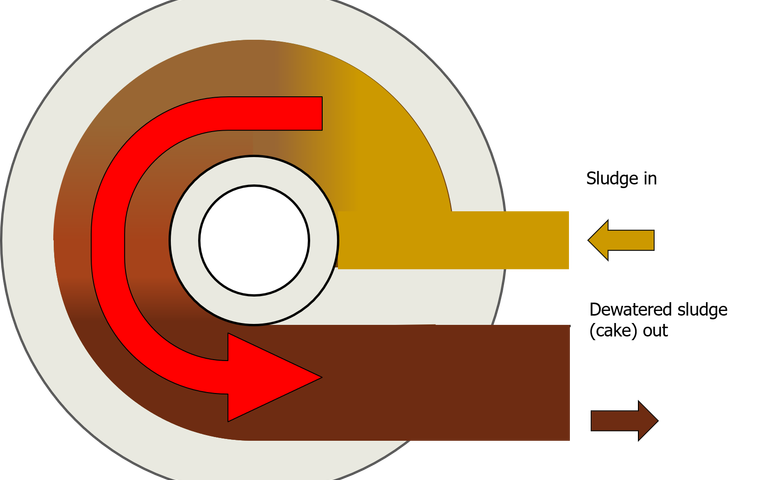

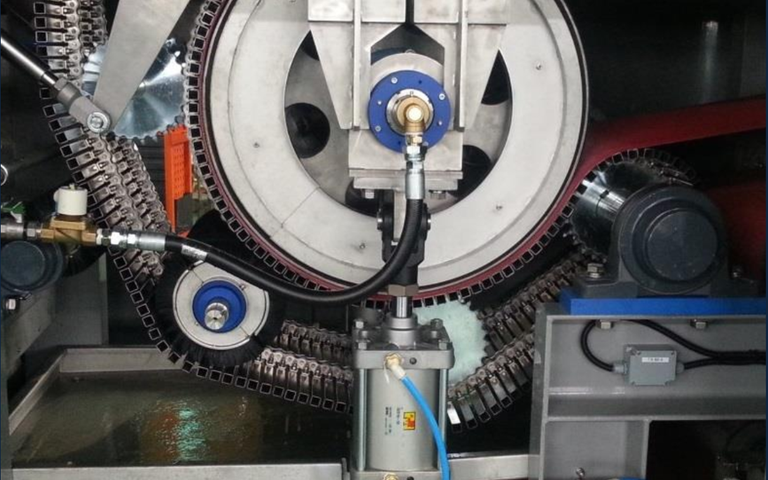

A screw press is a dewatering technology based on a slowly-rotating (~5 RPM) Archimedean screw within a cylindrical screen

Watermaths: Process Fundamentals for the Design and Operation of Water and Wastewater Treatment Technologies − available as an ebook

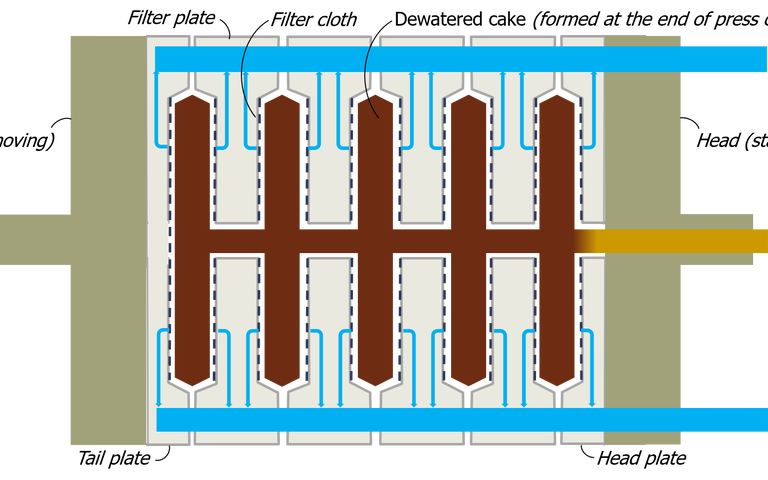

The filter press forces water from the sludge by applying high pressures to sludge layers held between rectangular plates

This technology removes water by passing the sludge through a narrow, rotating parallel-flow channel with porous walls

Centrifugation is used for thickening and dewatering sewage sludge − dewatered sludge has a higher dry solids concentration

Drying beds dewater sludge by allowing the liquid to drain and to evaporate. Lagoons provide dewatering through evaporation

Electro-dewatering technology provides enhanced removal by non-mechanical means through the application of an electric field

Film to demonstrate the stacked screw sludge dewatering machine from Benenv.

This solid-liquid separation equipment can be used for applications including municipal sewage, petrochemical, food & beverage, slaughterhouses and breeding, printing and dyeing, papermaking, leather, pharmaceutical and other industries.

The equipment is suitable for high and low concentration sludge (from 2000mg/L), and for all kinds of sludge with high and low viscosity, especially oily sludge.