Introduction to sludge conditioning

Overview of sludge conditioning

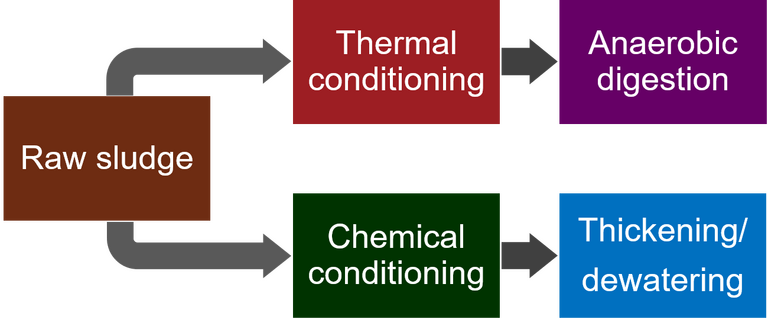

Sludge thickening and dewatering processes normally require pre-treatment to assist the separation of the water from the solids. This pre-treatment is referred to as conditioning, which takes the form of either:

- chemical conditioning, by dosing with inorganic coagulants (such as iron or aluminium) and/or organic flocculants (or polymers), or

- thermal conditioning by heating the sludge under controlled conditions.

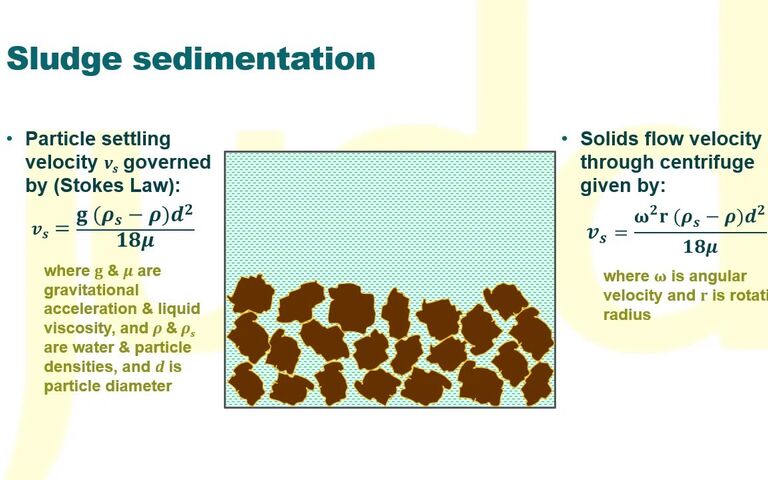

Chemical conditioning is designed to coalesce (or agglomerate) the smaller sludge particles (1−10 µm) to produce larger ones, and to reduce the colloidal (the sub-0.1 µm particle/macromolecular size range) content of the particulate matter. This then increases both the particle sedimentation rate and the permeability of the cake − the solids sediment formed from the particles. In doing so, the efficiency of the downstream thickening and dewatering processes is increased.

Thermal conditioning processes can be employed to improve the efficiency of both dewatering and anaerobic digestion and are usually based on either wet air oxidation or, most widely employed, hydrothermal treatment. This results in partial degradation of the sludge solids, making the resulting material more biodegradable as well as more dewaterable than the untreated sludge.