Pelletizers

Pelletizers features and blogs

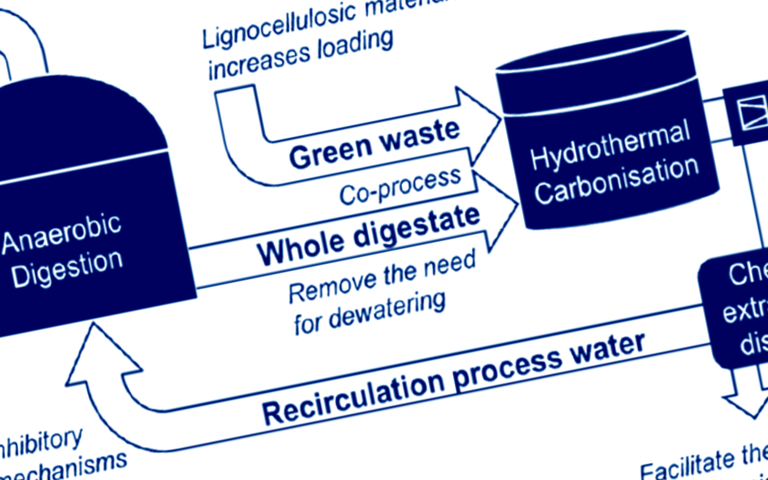

Co-processing of sewage digestate by hydrothermal carbonisation

Hydrothermal carbonisation (HTC) can be used to co-process anaerobic digestion (AD) digestate and lignocellulosic (or plant-based) feedstocks to improve the the hydrochar product quality. This AD waste co-processing route has been studied at bench scale. Read articleMore Pelletizers topics…

Convective dryers

Convective (or direct) dryers remove moisture from sludge by bringing the sludge particles into direct contact with hot gas

Belt dryers

Belt dryers comprise a conveyor belt which slowly transports the sludge solids through a stream of heated air

Flash dryers

Flash dryers use a rapid stream of rising hot air which both suspends and dries the solids.

Fluidised bed dryers

In fluidised-bed dryers the sludge particles are gently agitated and heated by a stream of upward-flowing pre-heated gas

Rotary drum dryers

Rotating drum dryers have a drum rotating at 4-8 RPM through which the sludge passes along with a stream of warm air

Conductive dryers

For conduction drying, the sludge is heated indirectly by bringing it into contact with a heated surface

Disc dryers

Disc dryers are based on vertical externally-heated discs or rings rotating in the sludge as it passes through the dryer.

Paddle dryers

Paddle dryers are based on externally-heated paddles rotating in the mass of sludge solids held in a stationary vessel

Solar dryers

Solar dryers comprise large greenhouses in which sludge is dried under the ambient conditions of the building.

-

Conditioning

Conditioning is the pretreatment of sludge upstream of thickening and dewatering to promote solid-liquid separation

-

Thickening

Thickening processes concentrate the sludge by removing part of the free water, such that the product can still be pumped

-

Dewatering

Dewatering processes mechanically remove a significant proportion of the sludge water to produce a 15-45% cake product

-

Drying

In sludge drying the sludge moisture is removed as water vapour by heating, generating a pelleted or powdered product

More process and operation topics…

Sludge stabilisation

Sludge stabilisation − alkaline stabilisation, lime and solids dosing, plus anaerobic and aerobic digestion

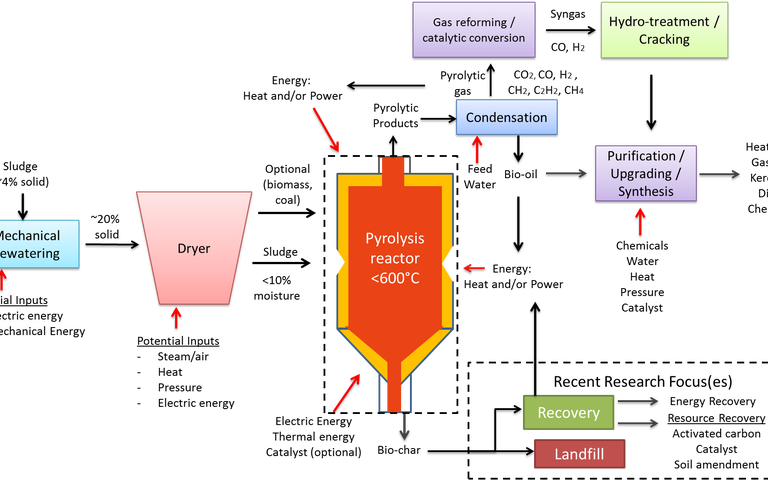

Thermochemical processes

Thermochemical methods are used to either significantly reduce the sludge solids content or pre-treat sludge upstream of AD

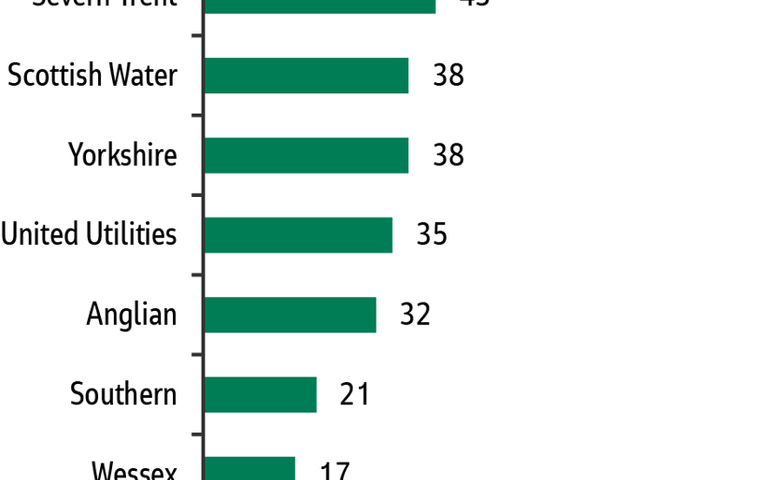

Sludge quality

Sludge is the main waste stream from the treatment of wastewater