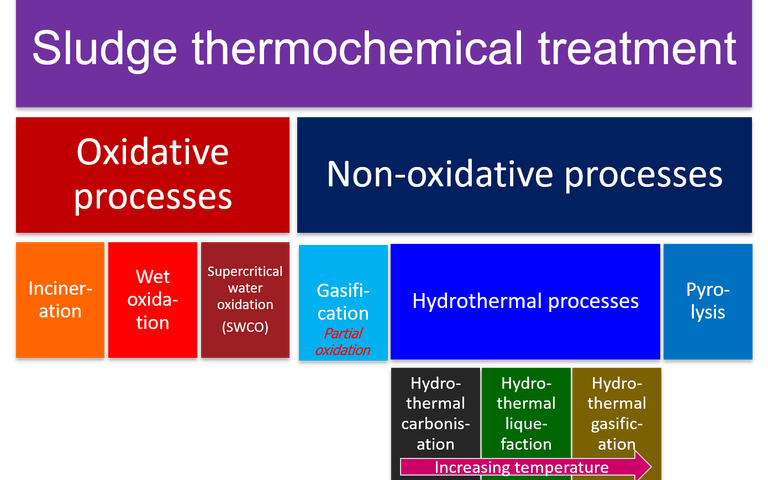

Sludge thermochemical treatment

An introduction to sludge thermochemical treatment methods

Your web browser is out of date.

Update your browser for better security, speed and to get the best experience on this website.

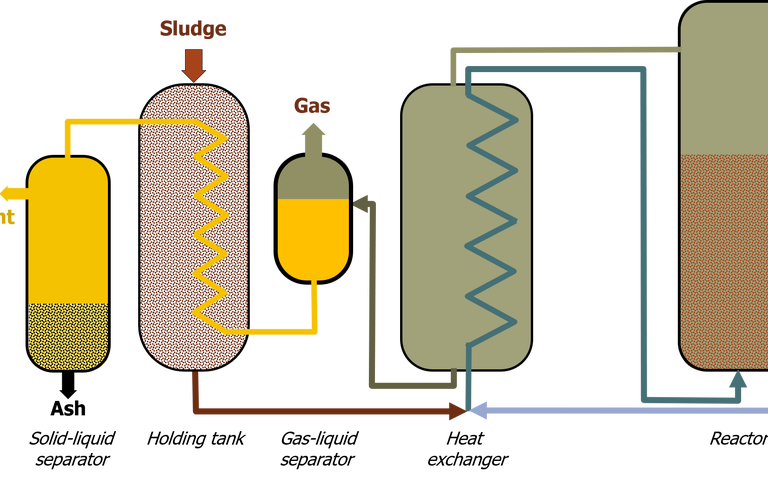

Wet or wet air oxidation of sludge is the thermal degradation, hydrolysis and oxidation of organic matter at elevated temperatures and pressures. The process does not generate secondary pollutants such as dioxin, furans, NOx (oxides of nitrogen) and SO2 (sulphur dioxide). It can be operated either to enhance the biodegradability of the sewage sludge or to substantially mineralise the organic matter (i.e. convert it to bicarbonate and carbon dioxide).

An introduction to sludge thermochemical treatment methods

Thermochemical methods are used for either degrading the sludge solids or pre-treating sludge upstream of anaerobic digestion

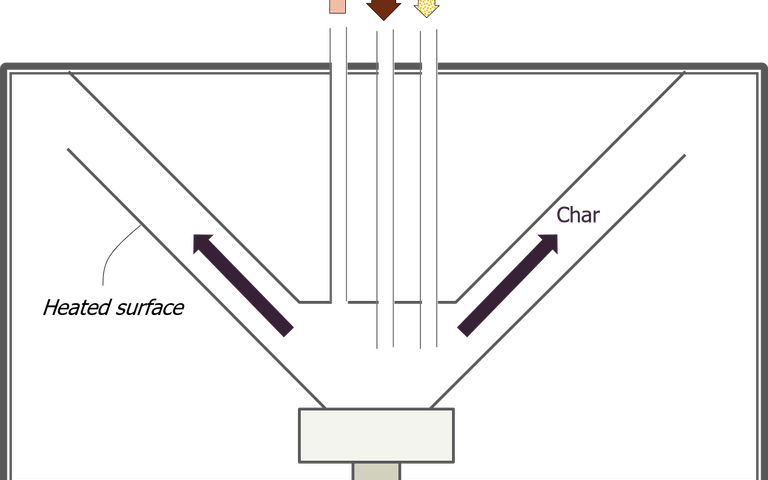

Various reactor configurations exist for sludge thermochemical treatment which vary in design, operation and application

An introduction to oxidative sludge thermochemical treatment methods

Wet/wet air oxidation of sludge is the thermal degradation, hydrolysis and oxidation of organics at high temperatures

Incineration oxidatively converts the sludge solids into gaseous and predominantly mineral products at high temperatures

Supercritical water oxidation (SCWO) refers to the rapid oxidation of organics in water in the supercritical phase of water

Oxidative methods for sludge thermal treatment comprise incineration, wet air oxidation and supercritical water oxidation

Non-oxidative thermochemical treatment of sewage sludge refers to treatment at elevated temperatures in the absence of oxygen

Thickening, dewatering and drying extract water from sludge to reduce the sludge volume

Sludge stabilisation − alkaline stabilisation, lime and solids dosing, plus anaerobic and aerobic digestion

Sludge is the main waste stream from the treatment of wastewater