Multi-disk screw press for thickening and dewatering

Multi-disk screw press for thickening and dewatering

-

Thickening, dewatering & drying

- Thickening

-

Dewatering

- Screw presses

-

Municipal Sludge

- Fresh Water Sludge

- Wastewater Sludge

- Industrial Sludge

Product description

The Multi-Disk Screw press (MDS) is a solid−liquid separator, which can achieve significant dewatering.

The sludge is thickened and dewatered progressively along the length of the vessel, which comprises a series of fixed and rotating rings, via the inner screw conveyor. The special tungsten carbide coating of the inner screw and its slow rotation reduces friction and assures a long life span of the system components. The filtrate is drained from the gaps between the rings, creating a thickening and a dewatering zone in different regions of the vessel. The sludge cake is discharged at the end plate, achieving a minimum solid content of 20%.

The advanced design of the MDS makes it a self-cleaning unit due to the friction free movement between the rings, is applicable across a wide range of sludge concentrations (2000 mg/L – 50000 mg/L), and is highly suited to oily sludge.

Model Numbers

- MDS131

- MDS201

- MDS202

- MDS301

- MDS302

- MDS351

- MDS352

- MDS401

Supplementary Services

- 24 hours online technical support via support@benenv.com

- IoT available

- Physical support available

Other directory listings from Benenv…

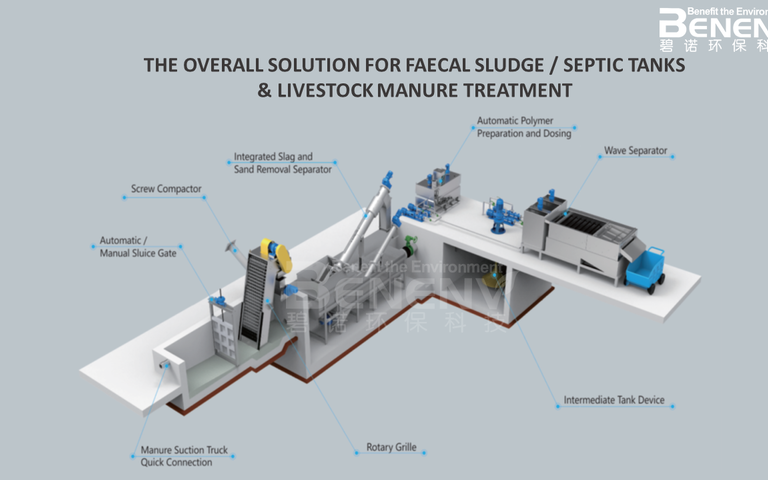

Faecal sludge treatment solution

Drying of pickling sludge

The Wave Separator for thickening and dewatering

Sludge carbonization − pig manure

Biological sludge treatment − overall solution

Pharmaceutical sludge dewatering

Sludge treatment equipment supply

About this page

This page was last updated on 11 November 2021

Disclaimer

Information on this page may have been supplied by third parties. You are reminded to contact any third parties to confirm information is accurate, up to date and complete before acting upon it. SludgeProcessing.com accepts no liability for information provided by third parties, actions taken on the basis of this information or information held on third-party websites.