How much is sludge worth?

Simon Judd

Assessing the value of sludge. Simon Judd, co-owner of SludgeProcessing.com, discusses the UK regulator OFWAT's view that where there’s muck, there's brass − and that sludge has a quantifiable value.

Here’s a question for you: How much is sludge worth?

The line taken by the UK regulator OFWAT is that sludge − or perhaps more specifically the biosolids generated from it − has a quantifiable value. Most often this value is equated to its calorific content, but there are increasing efforts to extract other resources from the sludge − phosphate from the sludge return liquors being the most obvious example.

And, of course, being a regulator, OFWAT is setting out rules as to exactly what the UK water companies (which are all private concerns) should be doing to try and realise the value of this most precious commodity. To kick things off, OFWAT has already stipulated information required concerning operations at each individual wastewater treatment works and sludge treatment site. This information includes:

- the sludge amounts

- the sludge dry solids and volatile solids content

- the nature of the wastewater treatment scheme from which the sludge was generated (and specifically the inclusion of exclusion of screening and degritting)

- the nature of the sludge treatment scheme (thickening/dewatering, chemical stabilisation, conventional/advanced AD, incineration), and whether or not the sludge has been screened

- the treated sludge quality

- whether or not sludge and wastewater treatment are co-located and, if not, how far the sludge is transported for treatment, and

- how much under or over capacity there is at each sludge treatment site.

So, there are quite a lot of figures which the water companies are obliged to provide, and they’re all placed in the public domain. But given this plethora of data, is it then possible to discern how much the sludge is actually worth? As with every other commodity, the profit generated from sludge is determined by the income minus the outgoings.

So, how much does the sludge cost?

Most people would say 'nothing'. It originates from all of us, and the British public give it to the UK water companies freely and magnanimously without expecting so much as a 'thank you' in return. But, again, it really isn’t that simple.

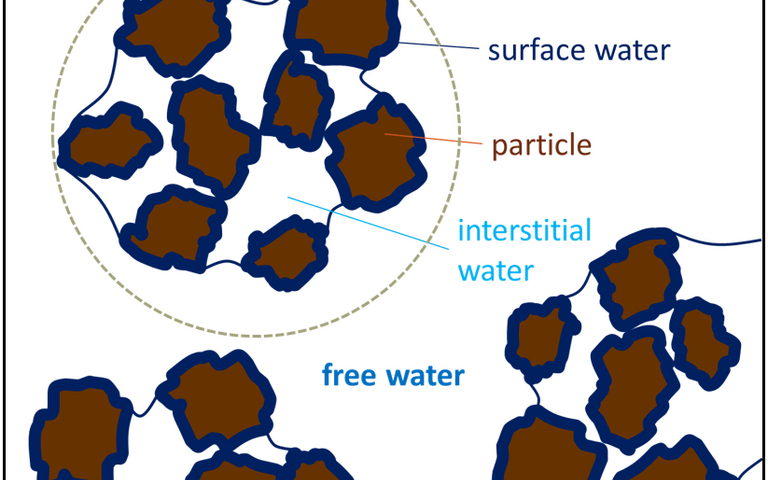

The reality is that processing sludge costs money. Operating expenditure is made up mainly of energy, chemicals and staff, and the capital equipment used is not cheap. Moreover, the quality of the sludge (and therefore it’s potential as a resource) depends on where it comes from in the treatment train – essentially primary sludge from the primary sedimentation stage and waste activated sludge (WAS) from the secondary biological stage.

This is all well and good as far as quantification is concerned. The sludge quality and volumes can be monitored (and, indeed, are now reported as part of this new exercise), and the companies presumably keep the receipts of all the equipment they’ve purchased. The income can be equated to the amount of the useful material produced (for example, the methane in the biogas from a digester) and its market value. In many cases, the overall value is primarily in displacing the externally supplied thermal energy through generating this energy on site from the sludge, and this is a simple enough calculation.

Where the real challenge comes is in how all the sludge treatment-specific expenditures can be separated from the wastewater treatment costs. Where can the line be drawn between two operations which are essentially interwoven?

At this point, a few challenges are clearly recognisable.

Let’s start with the electrical energy consumption. The electrical energy consumption of any wastewater treatment works is recorded. However, it’s rarely the case that the electricity consumed by the sludge operations (pumping, dewatering, etc) is recorded separately from the wastewater treatment side (mainly pumping and aeration).

Then there’s the labour costs. To get an accurate picture of the labour effort demanded by the sludge and wastewater processing individually would require some pretty specific timesheeting by the operators.

And lastly there’s the chemicals. It’s perfectly possible to log the chemicals usage against either wastewater or sludge, but it all adds to the workload of both the operators and the administrators.

And therein lies the rub. It’s fine to expect the water companies to extract value from waste − especially one produced in such prodigious amounts as municipal sludge. But to actually quantify the profit or loss is not straightforward if it has to be somehow disconnected from the wastewater treatment which generates the sludge in the first place.

It can even be argued, with some conviction, that such an enforced separation is ultimately a retrograde step. Resource recovery and achieving carbon neutrality is primarily about recovering carbon in a useful form: it’s of no consequence whether the carbon is in the solid or dissolved form so long as it is recovered and reused.

If the wastewater could be somehow treated directly by some super-charged anaerobic process, and the methane generated subsequently desorbed, then the sludge volumes would be so small as to be almost irrelevant. At the opposite extreme, if all the wastewater suspended carbon was removed by the finest of fine screens and the dissolved carbon adsorbed instead of aerobically degraded, then the wastewater treatment process could end up looking pretty similar to sludge treatment.

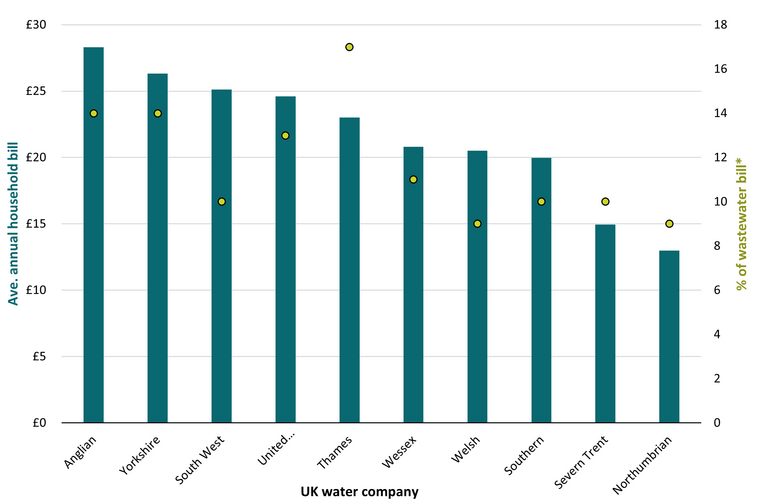

Finally, it’s worth maintaining a sense of proportion in all of this: the impact of any improved efficiencies is unlikely to be keenly felt by the customers. According to the latest data on OFWAT’s own web site (Fig. 1), the average household bill for bioresources (i.e. sludge processing and management) is around £1−2 a month. I think I speak for many customers of Anglian Water when I say that if they can snip 10−20% of this particular component of the bill then they are welcome to keep the profits for themselves – and maybe invest it in stockpiling the chemicals the UK water industry has run short of since Brexit.

There’s brass from muck, for sure, and all perceived wisdom is that resource recovery from sludge represents an opportunity well worth pursuing − both to minimise environmental impact and maximise the financial value. But maybe it’s better to just let the technology evolve, without trying to quantify everything and anything.