Managing anaerobic digestion biogas in sludge treatment

An introduction to managing AD biogas

A key aspect of the anaerobic digestion (AD) process is the generation of a biogas product which contains around 50-60% methane. The methane is a useful fuel, and must be removed from the gas stream prior to discharge since it is a highly active greenhouse gas.

Between 0.8 and 1.1 m3 of biogas is generated per kgVSS of organic matter by the AD process. The biogas can either be used directly on site in combined heat and power (CHP) co-generation or upgraded for export to the national gas grid.

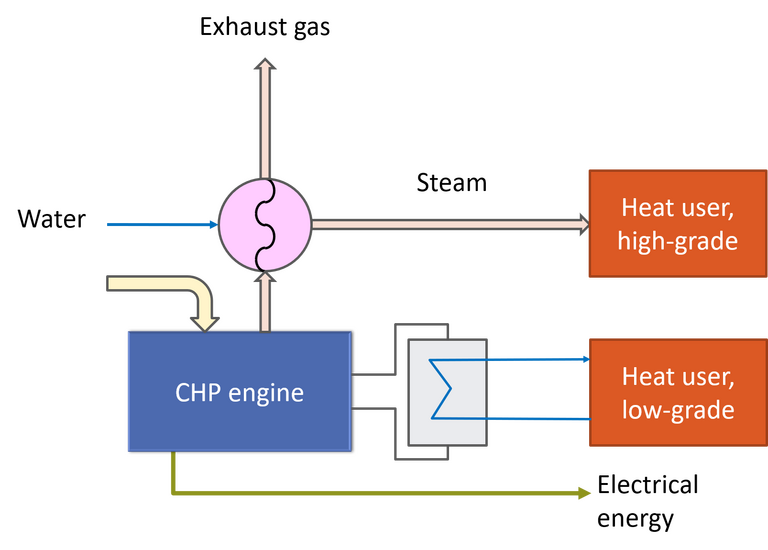

CHP engines generate both electricity and heat which are recovered using turbines and heat exchangers. Both these energy sources are usually used to power the site-based equipment; excess electrical power can be exported to the national electricity grid.

CHP engines use the energy generated from combustion of the gas to drive a crank shaft, which then turns an alternator to produce electricity. There are two sources of heat from the CHP engine:

- low-grade heat from the cooling circuits of the gas engine, and

- high-grade heat recovered from the exhaust gas.

The low-grade heat is recovered using heat exchangers, providing hot water (~90°C) that can be used to heat the digester tanks. The high-grade heat (~450°C) can be used to power driers or waste heat boilers, or possibly an organic rankine cycle unit, which is a process for converting heat into mechanical energy.